Welcome, tech enthusiasts! Today, we dive into the fascinating world of FS PCBA and how it can revolutionize electronic device performance. In this blog post, we will explore the various advantages of FS PCBA, including enhanced electrical performance, space optimization, reliability and durability, design flexibility, and cost-efficiency. Let’s explore how this technology is shaping the future of electronic devices!

Understanding FS PCBA:

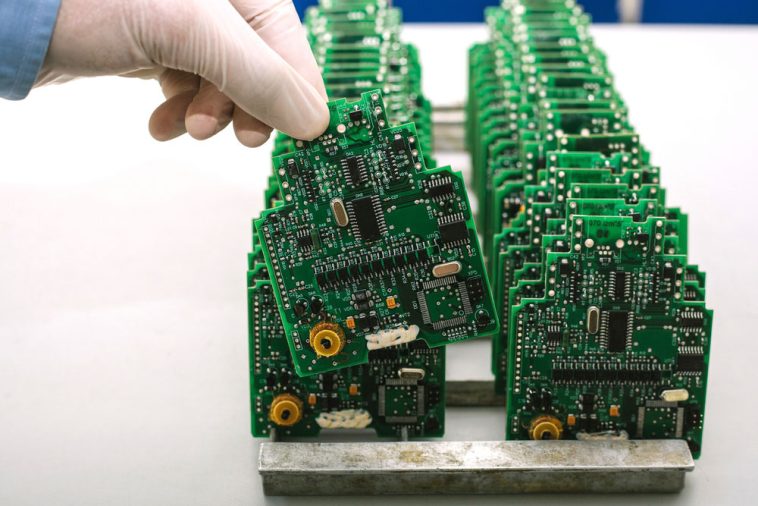

FS PCBAs, or Flexible Substrate PCBAs, are an innovative solution in the world of printed circuit boards. Unlike traditional rigid PCBs FS PCBS made with flexible substrates that offer numerous benefits. These flexible substrates are made from materials such as polyimide or polyester, which provide the necessary flexibility, durability, and compactness required for modern electronic devices.

Enhanced Electrical Performance:

One of the key advantages of FS PCBA is its ability to improve signal integrity. The flexible substrates used in FS PCBAs reduce impedance, resulting in cleaner and more reliable signal transmission. This improved signal integrity leads to increased speed and bandwidth capabilities, enabling electronic devices to handle high-frequency applications seamlessly. Whether it’s high-speed data transfer, wireless communication, or high-frequency sensor applications, FS PCBA can deliver exceptional electrical performance.

Space Optimization:

With the increasing demand for smaller and more compact electronic devices, space optimization has become crucial. FS PCBA offers a significant advantage in this area. The flexibility and compact size of FS PCBAs enable designers to create space-saving designs without compromising functionality. By utilizing FS PCBA technology, electronic devices can be made smaller, lighter, and more portable. This is particularly beneficial in industries such as wearables, IoT devices, and aerospace, where size and weight constraints are critical.

Reliability and Durability:

Electronic devices often face harsh environments, including temperature fluctuations, vibrations, and shocks. FS PCBAs are designed to withstand these challenges. The flexible substrates used in FS PCBAs exhibit excellent resistance to environmental factors, ensuring the reliability and durability of electronic devices. They can handle extreme temperatures, vibrations, and shocks without compromising performance. Case studies have shown that FS PCBA significantly enhances the lifespan of electronic devices, making them more reliable and robust.

Design Flexibility:

FS PCBA opens up a world of design possibilities for electronic devices. The flexibility of the substrates allows for unique form factors and unconventional designs that were previously impossible with rigid PCBs. From curved displays to flexible wearable devices, FS PCBA enables designers to push the boundaries of innovation. Additionally, FS PCBA offers customizability options for various applications, allowing manufacturers to tailor their designs to specific requirements. This flexibility in design is particularly valuable in industries such as automotive, medical devices, and consumer electronics.

Cost-Efficiency:

While FS PCBAs may initially seem more expensive than traditional rigid PCBs, they offer significant cost savings in the long run. The improved manufacturing processes involved in the production of FS PCBAs result in increased productivity and reduced material waste. Additionally, the smaller size and lighter weight of electronic devices enabled by FS PCBA technology can lead to cost savings in shipping, storage, and assembly. Although the upfront cost may be slightly higher, the overall cost-effectiveness of FS PCBAs becomes apparent when considering the entire product lifecycle.

Conclusion:

FS PCBA is a transformative technology that offers numerous advantages in enhancing electronic device performance. From improved electrical performance to space optimization, reliability and durability, design flexibility, and cost-efficiency, FS PCBAs are revolutionizing the electronic industry. As we continue to witness advancements in technology and the increasing demand for smaller and more powerful electronic devices, FS PCBA will play a crucial role in shaping our future. Keep an eye on this technology as it continues to evolve and bring exciting innovations to the world of electronics!

Closing Remarks:

Thank you for joining us on this exploration of FS PCBA and its advantages in enhancing electronic device performance. We hope this blog post has shed light on the incredible potential of this technology. As we move forward, let’s embrace the possibilities that FS PCBA brings and the opportunities it presents for creating more efficient, compact, and reliable electronic devices. Stay tuned for more exciting developments in the world of FS PCBA!

Key Benefits of FS PCBA:

1. Enhanced circuit connectivity:

FS PCBA ensures a strong and reliable connection between electronic components, reducing the risk of loose connections or poor conductivity. This results in improved overall performance and minimizes the chances of errors or malfunctions.

2. Reduced signal interference:

With FS PCBA, measures are taken to minimize signal interference, such as proper grounding and shielding techniques. This ensures that the electronic device operates without any disruption or noise, providing a stable and consistent performance.

3. Minimized component failure rates:

FS PCBA involves rigorous testing and quality control measures, which significantly reduce the chances of component failures. By identifying and rectifying any issues during the assembly process, FS PCBA ensures that the electronic device operates reliably over an extended period.