About HDPE Root Barrier

HDPE Root Barrier, also known as High-Density Polyethylene Root Barrier, is a specialized barrier system designed to prevent the spread of tree and plant roots in a controlled manner. It is commonly used in landscaping and construction projects to protect infrastructure, such as foundations, sidewalks, roads, and underground utilities, from potential damage caused by invasive root growth.

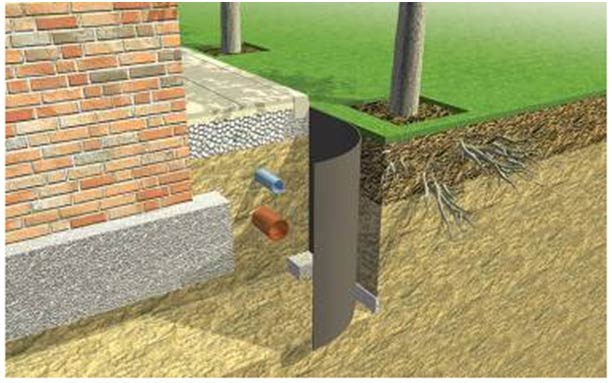

HDPE Root Barrier is made from high-density polyethylene, which offers excellent strength, durability, and resistance to environmental conditions. The barrier is typically available in the form of a thick, flexible sheet that is installed vertically into the ground, creating a physical barrier that redirects root growth.

The primary purpose of an HDPE Root Barrier is to guide the roots of trees and plants away from sensitive areas, preventing them from causing structural damage or interfering with underground utilities. By directing the root growth downward or laterally, the barrier helps maintain the stability and integrity of the surrounding infrastructure.

What are the Advantages of HDPE Root Barrier?

HDPE (High-Density Polyethylene) root barriers offer several advantages in managing and controlling root growth. Here are some of the key advantages of using HDPE root barriers:

Structural Protection: HDPE root barriers provide effective protection to infrastructure such as foundations, underground utilities, and pavement systems. They prevent root intrusion and potential damage caused by invasive root growth, ensuring the stability and integrity of structures.

Durability and Longevity: HDPE root barriers are known for their excellent durability and long lifespan. They are resistant to corrosion, moisture, chemicals, and physical impact, ensuring long-term effectiveness even in challenging soil conditions.

Flexible Design and Installation: HDPE root barriers are available in flexible sheets or rolls, allowing for easy installation and adaptation to different site configurations. They can be easily shaped, cut, and joined to create custom designs, making them versatile for various landscaping and construction applications.

Controlled Root Growth: HDPE root barriers guide root growth in desired directions, preventing invasive roots from spreading excessively or encroaching into restricted areas. This allows for controlled management of root systems, reducing the risk of damage to infrastructure.

Water and Nutrient Permeability: Some HDPE root barriers are designed with permeable sections, allowing the controlled passage of water and nutrients. This promotes the health of trees and plants while still providing root containment benefits.

Cost-Effective Solution: Installing HDPE root barriers can be a cost-effective solution compared to potential repairs or replacements of damaged infrastructure caused by uncontrolled root growth. They offer long-term protection, minimizing the need for costly maintenance or remediation.

Environmental Compatibility: HDPE root barriers are environmentally friendly as they help preserve the health and longevity of trees and plants while protecting nearby structures. They provide a balanced approach that maintains the benefits of green spaces while minimizing potential conflicts with infrastructure.

Low Maintenance: HDPE root barriers require minimal maintenance once installed. They are resistant to degradation, do not require chemical treatments, and can withstand the rigors of the surrounding environment, reducing the need for regular upkeep.

Versatility in Applications: HDPE root barriers can be used in various applications, including residential, commercial, and public landscaping projects. They are compatible with different soil types and can be installed during construction or retrofitted to existing sites.

How to Install a HDPE Root Barrier?

Installing an HDPE Root Barrier requires careful planning and execution to ensure its effectiveness. Here is a general step-by-step guide on how to install an HDPE Root Barrier:

Determine the Installation Area: Identify the specific area where the root barrier needs to be installed. This could be along a foundation, near underground utilities, or around sensitive structures.

Prepare the Site: Clear the installation area of any debris, rocks, or vegetation that may interfere with the installation process. Ensure that the soil is compacted and level.

Measure and Cut the HDPE Barrier: Measure the length of the installation area and cut the HDPE root barrier sheet to the appropriate size. Use a sharp utility knife or scissors to make clean, straight cuts.

Dig a Trench: Excavate a trench along the desired installation line. The trench should be wide enough to accommodate the width of the HDPE root barrier sheet and deep enough to create a secure barrier. The depth will depend on the depth at which you want to guide the roots.

Lay the Barrier: Place the HDPE root barrier sheet vertically into the trench, ensuring it extends above the ground level. The barrier should be positioned to guide the roots away from the desired area. If multiple sheets are needed, overlap them by several inches to create a continuous barrier.

Secure the Barrier: Backfill the trench with soil, firmly compacting it around the root barrier to provide stability and prevent movement. Ensure that the barrier remains in a vertical position and is securely anchored.

Finishing Touches: Once the trench is filled, level the surface and restore any landscaping or vegetation as needed. Water the area to settle the soil and promote root growth away from the protected area.

Monitoring and Maintenance: Regularly inspect the installed HDPE root barrier to ensure its effectiveness. Remove any vegetation or roots that may attempt to breach the barrier. Periodically check for any signs of root growth near the protected area and take necessary actions to redirect or trim the roots.

Is HDPE root barrier environment friendly?

Yes, HDPE root barriers are considered to be environmentally friendly. Here are some reasons why:

Biologically Inert: HDPE (High-Density Polyethylene) is a non-toxic and chemically stable material. It does not leach harmful substances into the soil or surrounding environment, making it safe for plants, animals, and groundwater.

Longevity: HDPE root barriers have a long lifespan, often lasting for decades without degradation. This reduces the need for frequent replacements, minimizing waste and environmental impact.

Resistance to Corrosion and Chemicals: HDPE is highly resistant to corrosion, moisture, and chemicals present in the soil. This durability ensures that the root barriers maintain their functionality and do not require additional chemical treatments or coatings.

Reduced Water Usage: HDPE root barriers are designed to redirect root growth, which can help conserve water. By guiding roots away from sensitive areas, such as underground utilities, water usage for maintenance and repairs can be minimized.

Preserving Existing Vegetation: HDPE root barriers allow for the preservation of existing trees and plants while managing their root systems. They provide a balance between protecting infrastructure and maintaining the benefits of green spaces.

Recyclable: HDPE is a recyclable material, meaning it can be reused or repurposed at the end of its life cycle. Recycling HDPE root barriers reduces the demand for virgin materials and contributes to a more sustainable waste management approach.

While HDPE root barriers offer environmental benefits, it is still important to follow proper installation practices and consider the specific site conditions and requirements. This helps ensure that the root barriers effectively control root growth while minimizing any potential impact on the surrounding environment.

About manufacturer of HDPE Root Barriers

Singhal Industries is a renowned and reputable manufacturer of HDPE Root Barriers, offering top-quality products that consistently meet and exceed customer expectations. With a strong commitment to excellence, Singhal Industries has established itself as a leading brand in USA for manufacturing these barriers.

Singhal Industries takes great pride in its ability to consistently meet customer requirements. Their team of highly trained and experienced professionals ensures meticulous attention to detail and stringent quality control during the manufacturing process. By adhering to international standards, Singhal Industries guarantees the reliability and durability of their HDPE Root Barriers.

Customer satisfaction is paramount to Singhal Industries, and they go above and beyond to fulfill customer demands. They provide customized solutions tailored to address specific needs and requirements. Singhal Industries maintains a strong and positive relationship with customers by exceeding their expectations and delivering products of superior quality.

For those in search of HDPE Root Barriers in USA, Singhal Industries is a trusted and renowned choice. Their unwavering commitment to quality, adherence to international standards, and customer-centric approach distinguish them in the market. By selecting Singhal Industries, customers can have confidence in receiving reliable products and a gratifying experience.

In summary, Singhal Industries is a respected brand in USA, known for manufacturing high-quality HDPE Root Barriers. Their emphasis on quality control, compliance with international standards, and dedication to customer satisfaction make them the preferred choice for customers seeking reliable and effective root barrier solutions.