In the dynamic landscape of modern industries, ensuring environmental sustainability and regulatory compliance is a top priority. Environmental monitoring systems play a critical role in this endeavor, providing industries with real-time insights into their impact on the environment. These systems are designed to monitor various aspects of industrial operations, from emissions and air quality to water usage and waste management. In this blog, we’ll explore how environmental monitoring systems function within an industrial premise, ensuring responsible practices and a healthier planet.

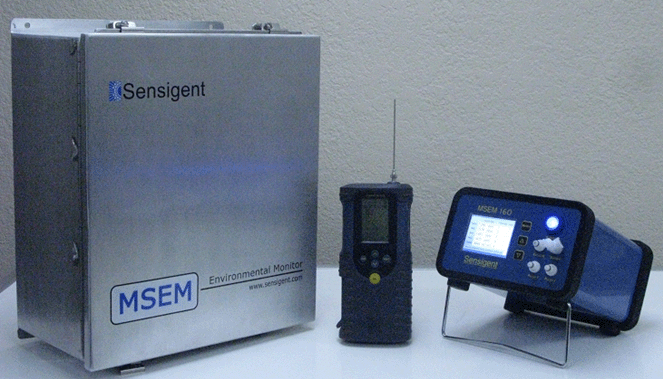

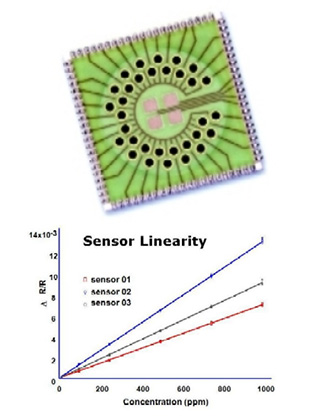

1. Sensors Deployment and Data Collection

Environmental monitoring systems begin by strategically deploying a network of sensors throughout the industrial facility. These sensors are designed to measure a wide range of parameters, including air quality, temperature, humidity, noise levels, particulate matter, volatile organic compounds (VOCs), and more. In addition, sensors may also monitor water quality, waste generation, and energy consumption. The data collected by these sensors provides a comprehensive overview of the environmental conditions within the facility.

2. Continuous Data Gathering

Once deployed, these sensors continuously gather data at specified intervals. The frequency of data collection ensures that changes in environmental conditions are captured in real time. For example, emissions from manufacturing processes, chemical reactions, and other activities can be monitored to prevent any breaches of air quality standards.

3. Data Transmission and Centralization

The collected data is transmitted to a centralized system, often referred to as a Supervisory Control and Data Acquisition (SCADA) system. This system serves as the hub for data storage, analysis, and reporting. The data can be transmitted through wired or wireless communication channels, ensuring that information from various sensors is integrated for comprehensive analysis.

4. Data Analysis and Interpretation

In the SCADA system, sophisticated algorithms and models analyze the collected data. The analysis aims to identify trends, patterns, and anomalies that could indicate potential environmental concerns or deviations from regulatory standards. For instance, sudden spikes in emissions or unusual changes in air quality parameters can trigger alerts for further investigation.

5. Alert Systems and Notifications

Environmental monitoring systems are equipped with alert systems that notify personnel when specific thresholds are exceeded. These alerts prompt immediate action, enabling facility managers to address issues promptly. For example, if the emission levels of a pollutant cross a predefined limit, an alert is sent to relevant personnel, ensuring timely mitigation measures.

6. Regulatory Compliance Monitoring

One of the primary functions of environmental monitoring systems in an industrial setting is to ensure compliance with environmental regulations and permits. These systems assist industries in adhering to emission limits, waste disposal guidelines, and other regulatory standards set by governing authorities.

7. Efficiency and Resource Management

Beyond compliance, environmental monitoring systems also contribute to efficient resource management. By monitoring energy consumption, water usage, and waste generation, industries can identify opportunities for optimization and cost reduction while minimizing their environmental footprint.

8. Reporting and Documentation

Environmental monitoring systems generate comprehensive reports that document the facility’s environmental performance over time. These reports are valuable for regulatory reporting requirements and internal audits. They provide a historical record of environmental data that can be analyzed for trends and used for strategic decision-making.

9. Continuous Improvement and Sustainability

The insights derived from environmental monitoring systems enable industries to implement continuous improvement strategies. By identifying areas with high emissions or resource inefficiencies, facilities can implement corrective actions and sustainable practices to minimize their environmental impact.

10. Public Relations and Transparency

Industries that prioritize environmental monitoring and sustainability often enjoy improved public relations and a positive image. Sharing environmental performance data with stakeholders, investors, and the public demonstrates a commitment to responsible practices.

Benefits of Environmental Monitoring Systems in Industries

- Environmental Protection: These systems prevent environmental degradation by monitoring emissions, waste, and resource consumption, ensuring that industries operate within acceptable limits.

- Regulatory Compliance: Industries can easily track their compliance status, reducing the risk of penalties and legal consequences.

- Early Detection and Mitigation: Rapid identification of environmental concerns allows for timely intervention and mitigation measures, preventing potential hazards.

- Operational Efficiency: Monitoring resource consumption helps industries optimize processes and reduce operational costs.

- Data-Driven Decision-Making: The data generated by these systems informs decision-making for sustainability initiatives, process improvements, and strategic planning.

In conclusion, environmental monitoring systems are an integral part of modern industries aiming for sustainability and regulatory compliance. By combining sensor technology, data analysis, and alert mechanisms, these smart sensor solutions ensure responsible practices, efficient resource management, and the protection of our environment. As industries continue to evolve, the role of environmental monitoring systems becomes even more critical in achieving a harmonious balance between economic growth and environmental stewardship.